Categories

New Blog

Do you know process of Gravure Ink?

Apr 25, 2021•Film properties : scratch resistant, heat resistant, oil resistant

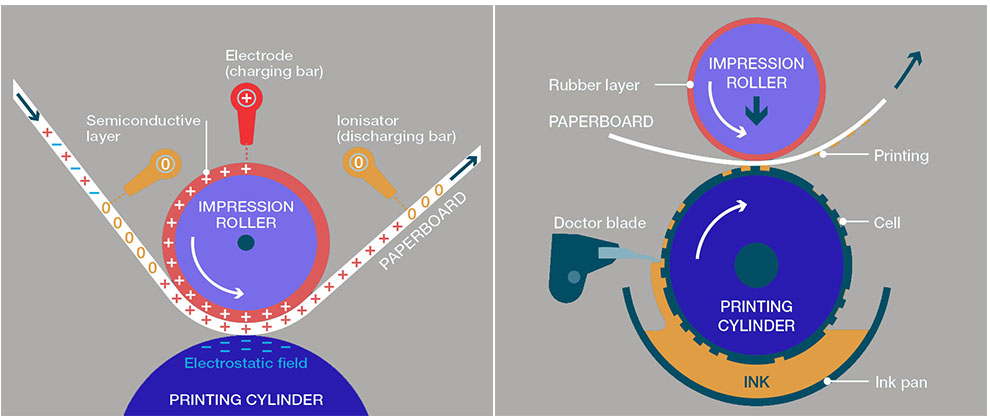

While the press is in operation, the metal printing cylinder is partially immersed in the ink tray, filling the recessed cells, which are intaglios on the cylinder. As the cylinder rotates, it draws excess ink onto its surface and into the cells. The doctor blade removes the excess ink, leaving in the cells the right amount of ink required before it makes contact with the paper. Next, the paperboard gets sandwiched between the impression roller and the gravure printing cylinder, where the ink gets transferred from the recessed cells to the web. The purpose of the impression roller is to apply force to ensure even and maximum coverage of the ink. The inked paperboard then goes through a dryer because it must be scorched before going through the next color unit and accepting another coat of ink.

Principle of gravure printing