Features:

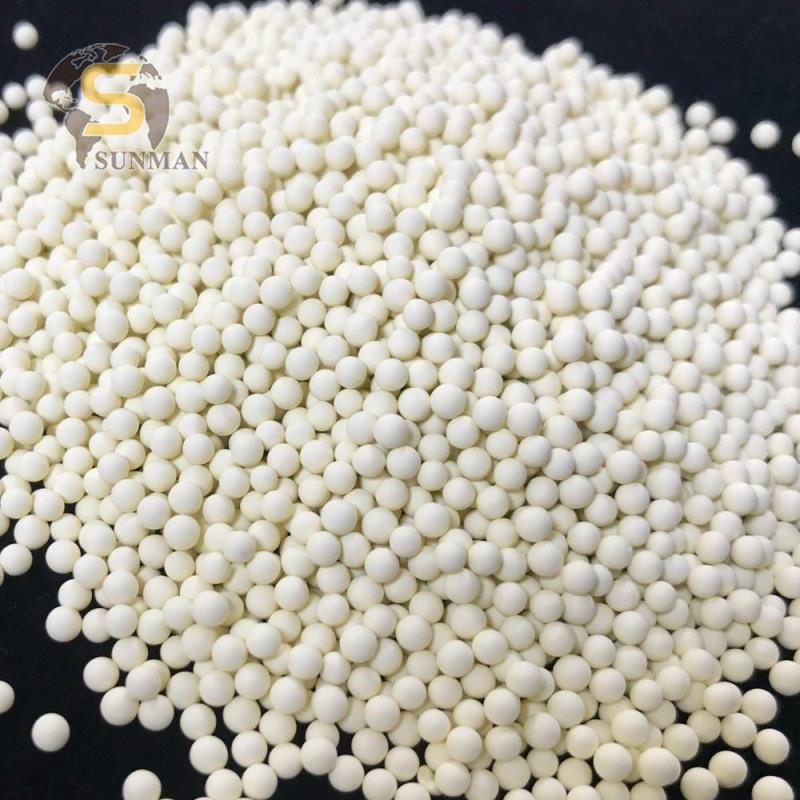

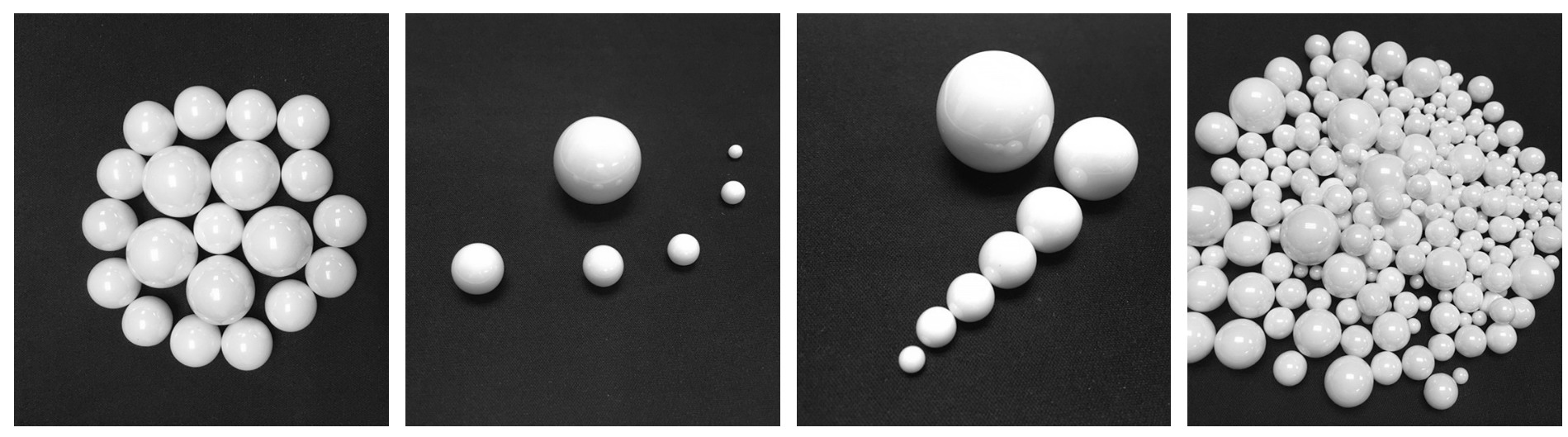

• Good roundness, smooth surface, brightness, high density, high strength,

inertia and hardness, perfect grinding medium.

• Good stability, strong acid resistance and alkali proof.

• Have excellent toughness, strength, impact resistance, not broken.

• Minimum of wear and tear on equipments and best grinding media.

Typical Properties:

|

Specific Gravity |

>6.0kg/dm3 |

|

Bulk Density |

>3.6kg/L |

|

Hardness Mohs |

9 |

|

Hardness Vickers |

>1200kg/mm2 |

|

Crushing Strength |

12000N(5mm) |

|

Color |

Ivory |

|

Size: |

Φ0.1, Φ0.2, Φ0.3, Φ0.4-0.6, Φ0.6-0.8, Φ0.8-1.0, Φ1.0-1.2, Φ1.2-1.4, Φ1.4-1.7, Φ1.5-2.0, Φ2.0-2.5, Φ3, Φ4, Φ5, Φ8, Φ10…or any customize sizes. |

Applications:

1.grinding and dispersion of coatings and paints.

2.organic/inorganic pigments, e.g. titanium dioxide, ultra marine, iron oxide, etc.

3.pigments to dye textiles, plastics and food.

4.electric ceramics, e.g. barium titanate, piezoelectric ceramics, sensors, condensers.

5.medical technology, e.g. dentures and hip prosthesis.

6.magnetic ceramic, ferrite.

7.technical ceramic components, e.g. exhaust cultivator in engine technology.

8.dispersion of fungicides, herbicides, insecticides.

9.grinding of pigments and solids for lipsticks, skin and sun protection creams.

10.nano grinding for the production of active substances and supplies substances.

Chemical Composition:

|

Composition |

ZrO2 |

Y2O3 |

|

Wt% |

95 |

5 |