Property:

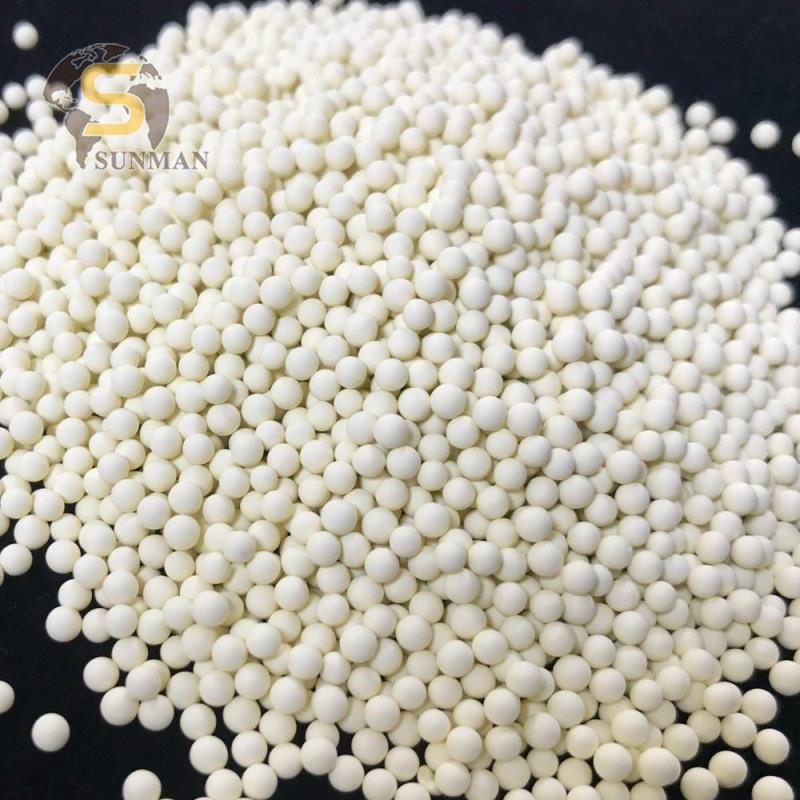

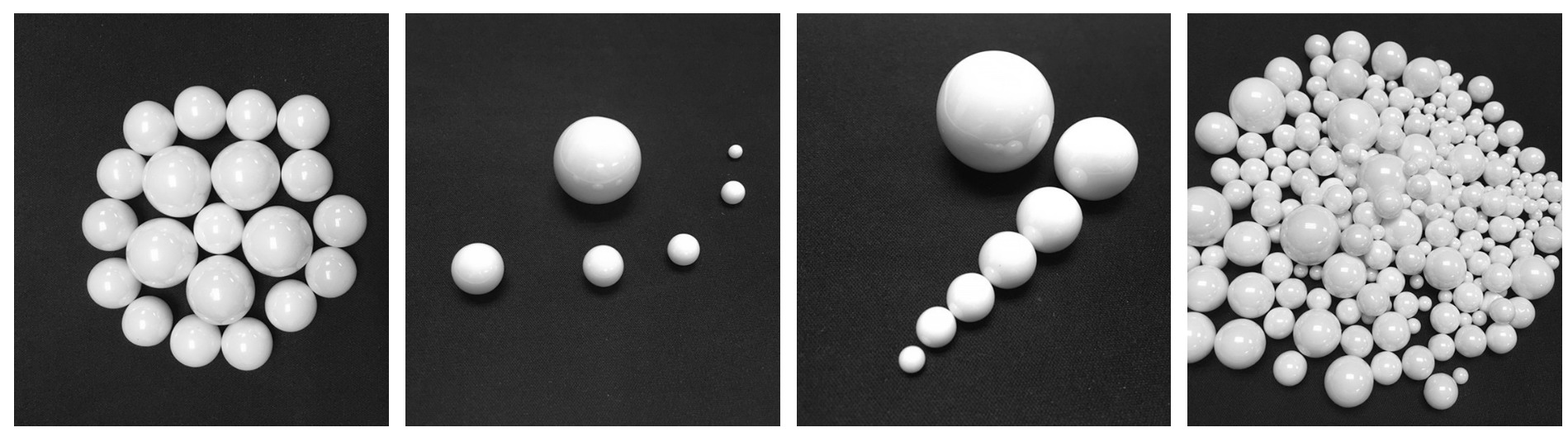

1.Good roundness,smooth,bright and without pores.High density, high efficiency

2.High strength, high toughness, impact resistance and no breakage.

3.Good stability, acid and alkali resistance.

4.Low wear resistance, minimal wear and tear to equipment, and high cost performance.

*Paint, printing ink ,pigment etc.

*Minerals such as zirconium silicate,GCC, Kaolin clay

*Powder such as Titanium pigment, alumina powder, zircon sand, silicon powder

*Medical,cosmetic, biochemistry

*Agrochemical product

Specification:

|

ZrO2 Content |

Main Composition |

Specific Gravitys |

Bulk Density |

Moh's Hardness |

|

7% |

ZrO2+Al2O3+SiO2 |

2.75±0.1 g/cm3 |

1.75±0.1 g/cm3 |

7~8 |

|

15% |

ZrO2+Al2O3+SiO2 |

3.0±0.1 g/cm3 |

1.75±0.1 g/cm3 |

7~8 |

|

35% |

ZrO2+Al2O3+SiO2 |

3.2±0.1 g/cm3 |

2.0±0.1 g/cm3 |

8 |

|

50% |

ZrO2+Al2O3+SiO2 |

3.7±0.1 g/cm3 |

2.3±0.1 g/cm3 |

8~9 |

|

80% |

ZrO2+Al2O3+SiO2 |

5.4±0.1 g/cm3 |

3.3±0.1 g/cm3 |

8 |